Posted by Al Voth on 2024 Feb 8th

Reloading Crimped Brass - Inside MDT

In my last posting, we looked at some best practices for reloading cartridge cases that were scavenged from sources like shooting ranges. However, there wasn't room to examine how to work with cartridge cases that have crimped primer pockets, a condition that warrants a follow-up discussion.

More: Scavenging Brass

Cartridge cases with crimped primer pockets are some of the easiest to obtain as they are commonly used by the military, security, law enforcement, and the general public. All of which are high-volume users who don't reload. These cases' easy availability and rejection by many handloaders means they are also the cheapest when purchasing once-fired brass.

Additionally, it might be all that's available for some hard-to-find calibers. For example, I've been working with the 224 Valkyrie and the 6mm ARC, and in both instances, the factory ammo I've been able to find—and will be reloading—has crimped primer pockets. This brass is rare enough that I'll do whatever is needed to remove those crimps.

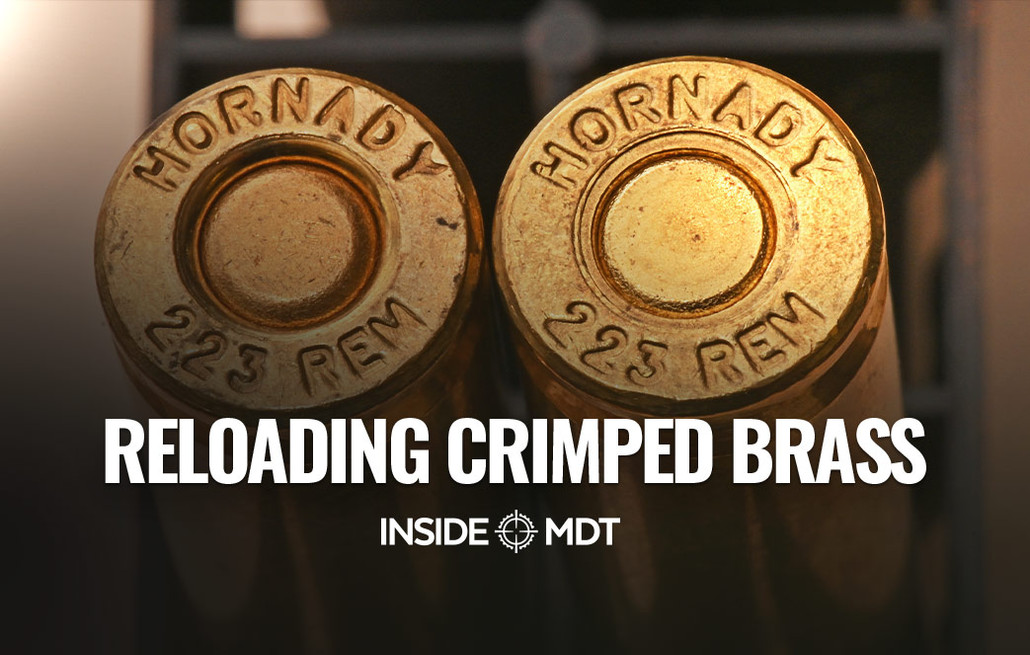

Fortunately, crimped primers are easy to recognize. These days, most manufacturers crimp with a circular stamp around the circumference of the primer. Although I have seen crimps that take the form of triangular stab marks, sometimes in a star shape, the circle crimp is certainly the most common.

WHY DO MANUFACTURERS CRIMP CARTRIDGES?

The purpose behind crimping is found in the rough handling these cartridges get in semi and full-auto firearms. Having a primer back out causing functioning problems is not desirable when lives are on the line. It can happen either in the feeding/chambering process or after firing if pressures skyrocket. Thus, The primer is held in place by both the friction fit into the pocket and the crimp, reducing the chances of primer-related malfunctions. It's a belt-and-suspenders type of precaution, but it's worth the extra step.

Here, the right-hand primer has been crimped in place, while the left-hand one has not.

During the crimping process, cartridge case metal immediately surrounding the primer pocket has been "moved" slightly into the primer pocket to lock the primer in place. This means removing the old crimped-in primer does take a bit more effort than a non-crimped one. So, I prefer to use a dedicated depriming die for this operation rather than perform this function during the re-sizing operation. After that, only two methods are used to remove the crimp and prepare the case for reloading—swaging and reaming. Fortunately, it only needs to be done once and not repeated for subsequent reloading.

SWAGING

As the name implies, swaging removes the old crimp by simply pushing the metal out of the primer pocket and reforming that pocket to its original dimensions. Naturally, most of the major reloading manufacturers have versions of tools that do this job. Some are intended for high-volume work, while others are best suited to low or mid-volume projects. I'm told the Dillon tool is an excellent option for those with a lot of brass to process, but I haven't used it. The RCBS tool is a good option for those processing smaller quantities of brass, but it takes some time to get adjusted perfectly. No matter the brand, all swaging tools need to be set up for either large or small primer pockets and typically come with the tooling to handle either size.

This RCBS primer pocket swager fits in a single-stage press and removes the crimp from both large and small primer pockets.

REAMING

Unlike swaging, reaming removes metal from the primer pocket by cutting it out rather than displacing it. Reaming is as effective as swaging, but it is typically slower when done by hand. However, there are ways to motorize the process (which speeds things up considerably). Additionally, there are dedicated reaming tools for primer pockets, but I've always had good luck using the RCBS tool intended for neck chamfering. With the case in one hand and the reamer in the other, a firm press into the primer pocket and a couple of coordinated twists will usually do the trick. Using a motorized system, start with a light touch, evaluate the results, and aim for consistency.

Primer pocket crimps can be removed by reaming, here with an RCBS neck chamfering tool.

CAUTION AND FINAL THOUGHTS

As with swaging, reaming a primer pocket can be overdone, leaving the primer pocket too large and the primer not sufficiently supported. Either process takes a little trial and error to get the tooling set correctly or develop a feel for how much metal to remove. It's always best to process one or two cases first, then try and seat a few primers, determining by feel if they seat into the pocket about the same as in a non-crimped case. Once the correct amount of swaging/reaming has been nailed down, only then should you process cases in quantity.

It's also worth mentioning that many cases with crimped pockets originate from military-spec ammo. These cases can be of heavier construction to withstand the rigors of use in automatic firearms. Therefore, they may have reduced internal capacity. Always check for this when encountering cases with crimped primer pockets, as it may be necessary to reduce powder charges to maintain safe pressure levels.

Considering the cartridge case is the most expensive component in a round of ammunition, any savings regarding it can pay off dramatically. And if it means removing the crimp from some primer pockets to get that saving, it's usually well worth the time and effort involved.

Getting ready to send some reloads down range.

RELOADING RESOURCES FROM MDT

- 6mm GT Load Development

- Ultimate Reloader 6GT Precision

- Fire Forming and Loading 223 AI

- Loading 6GT with Hodgdon H4350

- Loading 6MM ARC AND .223 Remington with a Dillion Progressive Press

- A Look at Reduced Loads

- Crimping Handloads

- Scavenging Brass

ABOUT THE AUTHOR

Al Voth calls himself a "student of the gun." Retired from a 35-year career in law enforcement, including nine years on an Emergency Response Team, he now works as an editor, freelance writer, and photographer and keeps active as a consultant in the field he most recently left behind—forensic firearm examination. He is a court-qualified expert in that forensic discipline, having worked in that capacity in three countries. These days, when he's not working, you'll likely find him hunting varmints and predators (the 4-legged variety).

CAD

CAD

Euro

Euro