Posted by David Henry on 2022 Oct 6th

LOADING 6MM ARC AND .223 REMINGTON WITH A DILLON PROGRESSIVE PRESS

I am a huge fan of the Dillon 750XL for loading my ammunition. I have found the Dillon perfectly adequate for loading the match .223 and 6mm ARC I use in my competition bolt guns. In this article, I will share the steps I use to reload precision rifle ammunition on a progressive press. Let's begin.

More: HORNADY 6mm ARC for Competition

DECAPPING, PRIMER POCKETS, AND ANNEALING

When I return home from the range, I like to decap all my brass with the Mighty Armory decapping die. I once had a case of loose primer pockets on some 6GT brass, and so now it's a habit to check every primer pocket with a go/no go gauge. After that step, I grab my AMP (Annealing Made Perfect) annealer and anneal every piece of brass after each firing to ensure I'm as consistent with sizing. After all my cases are annealed, I use a small bit of imperial sizing wax, wipe down the cases, and then run them through a full-length sizing die.

Annealing Made Perfect annealer. I have found that annealing will extend the life of my brass.

NECK TENSION AND TUMBLING

After the batch of brass has been resized and returned to the proper headspace, I switch to my mandrel. I'm currently using a K&M mandrel with .002 under bullet diameter to create a neck tension that I'm happy with. After that, the brass goes straight into the wet tumbler with stainless steel media. As soon as I have several hundred cases in my tumbler, I'll start tumbling. I use a Frankford Arsenal wet tumbler and their cleaning liquid. After about 45 minutes to an hour, I pull all the cases out, separate them, and dry them, ensuring no media is stuck in the cases or in the neck. After letting the cases dry completely, I move on to the next step.

Frankford Arsenal wet tumbler with stainless steel media.

TRIMMING AND CHAMFERING

For me, the next step in brass prep is trimming the brass and chamfer inside and outside. I lean on the Harrison Precision case trimmer to do all my trimming and chamfering. Now that I have fired, collected, de-capped, annealed, sized, cleaned, and trimmed the brass, the progressive press comes into play. I have found these procedures extend the life of my brass.

Harrison Precision case trimmer.

PRECISION LOADING WITH A DILLON 750XL

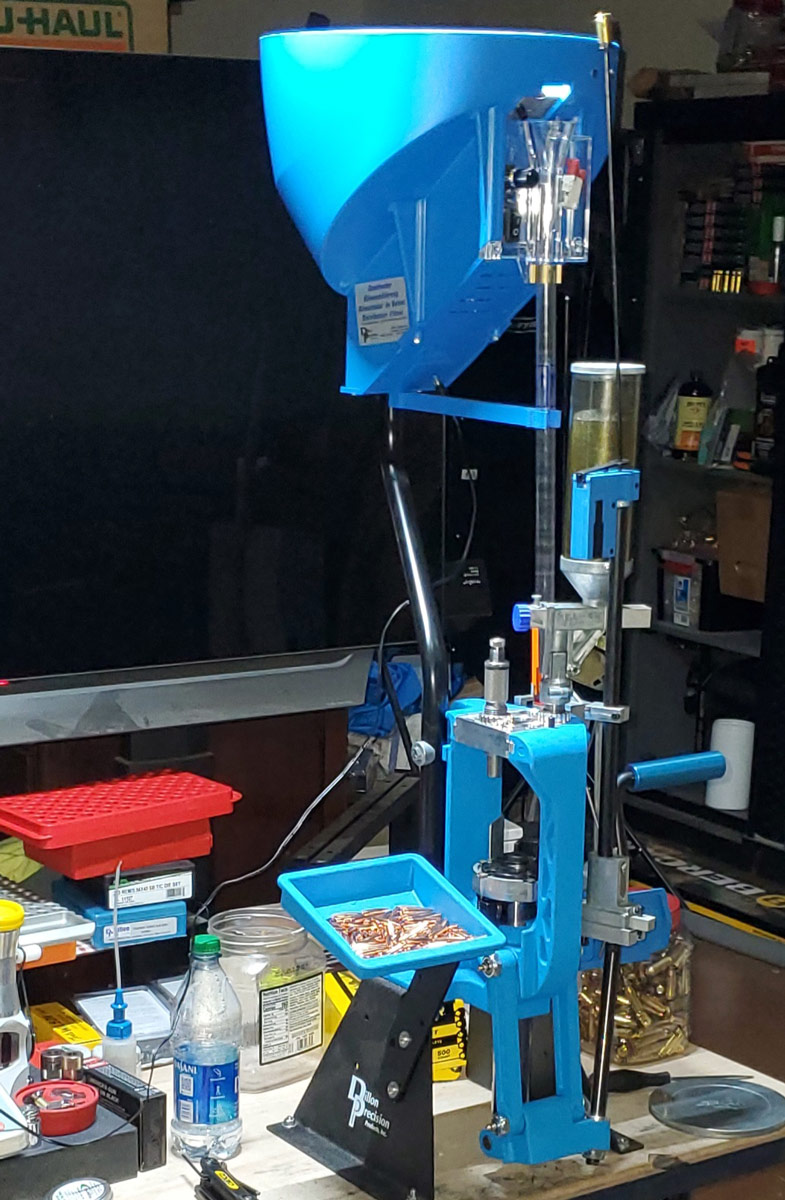

Once brass preparation is done, it is time to start loading. As previously mentioned, my preferred progressive press is the Dillon 750XL. I currently load match ammo for both .223 and 6mm ARC on my Dillon 750XL and use the factory Dillon powder drop for both cartridges. With .223, I'm using Shooters World Precision because it meters well through the slide bar powder drop. For the 6 ARC, I'm using LEVERevolution- a spherical propellant that also meters well through the Dillon powder drop.

Dillion 750 XL. Great for making a lot of high quality ammunition.

When it comes to setting up the die for the .223 I bring up the sizing die far enough that it's just the expanding mandrel going through the neck on the first step. On the second step, I prime the case and then fill it with powder. The third step is optional, but I run a powder check to make sure I have powder distributed into the case. Then I'll seat the bullet in the next step. If I use it, the fifth stage will involve the crimp. I usually don't crimp my 6 ARC, but I do a light cramp on my .223. This process has produced exceptional loads for both my .223 and my 6 ARC bolt guns.

Specs on the loads:

- .223 Remington I run 85.5 grain Berger Hybrid with Shooters World Precision powder and CCI small rifle magnum primers or CCI 450.

- 6mm ARC I use the same CCI small rifle magnum primers, a 105 Berger Hybrid. The powder of choice for that round is LEVERevolution.

Author’s personal 6mm ARC in an MDT Chassis System.

CLOSING THOUGHTS

If you shoot high-volume PRS competitions, it's always nice to be able to save some time by using your progressive press to load your rounds. In my personal experience, I never have enough ammo loaded or lying around for the next match. Using a progressive press saves me a ton of time and allows me to produce quality match ammunition for the calibers I commonly use. When you have limited time because you work all day long but need 200 to 300 rounds for the following weekend, this is one way to get the job done.

ADDITIONAL LOADING RESOURCES FROM MDT

- Fire Forming and Loading 223 AI

- Crooked Ammunition and Accuracy

- Loading 6GT with Hodgdon H4350

- 6mm GT Load Development

- HORNADY 6mm ARC for Competition

- A Look at Reduced Loads

- ANALYSIS: 6MM BR NORMA

ABOUT THE AUTHOR

I have 20+ years in the automotive industry- first managing shops in the northwest for over 13 years and now as a factory rep for Hunter Engineering. I love my family, my faith, and my firearms. I've shot competitively in the PRS southwest region for two years. I also compete in long-range AR-15 competitions at least once a month and am an avid reloader. I have written for Ballistic Magazine's 'Ballistic Best' precision rifle edition for two years. My other hobbies include photography, videography, woodworking, and knife making. You can find me on Instagram @davidinthesun

CAD

CAD

Euro

Euro