2022 Apr 7th

BUILDING A TRAINING RIFLE - PART 1

The main idea of having a training rifle is to get your live-fire practice in without burning out your match barrel or eating up your match ammunition and ammunition components. There are a few different trains of thought for a competition training rifle and cartridge.

They are as follows:

- A rifle with more recoil, so when you shoot your match rifle, the recoil is noticeably more controllable. The most popular in this category would be .308 Winchester. I typically use .308 to strictly practice fundamentals on a somewhat antiquated platform similar to an M40A5 without training wheels.

- A rifle that shoots a lighter cartridge like .223 Remington or .22 Long Rifle. These small calibers are cheaper to shoot and have minor recoil, which equals more practice. Both are available at your local gun store, and handloading is not required.

- A third option is something either with the same or similar chambering so that there isn't much or any difference when you go from training to the match rifle—for example, a 6mm GT and a 6 Creedmoor. The main benefit here is that you aren't cooking your match barrel.

More: Rimfire Redemption: The Case for a 22 Rifle

Now that you have decided which cartridge you'll be using, it's time to think about the actual build. Are you using the same rifle and just swapping out the barrel? A few actions allow you to quickly change your barrel with only an Allen wrench. For example, the Terminus Zeus and the Curtis Vector have a system where you hand tighten the barrel and torque down set screws through the action onto the barrel tenon.

If your barrels are head spaced properly when torqued, you could also just use a barrel vise and an action wrench and swap barrels. You could also build a pair of rifles, one for training and one for competition, and set them up as close as possible. This is what I chose to do. Let's look at my training rifle build.

THE RIFLE BUILD

My match rifle is a 6mm GT in an MDT ACC Chassis. It's gone through a couple of changes since last season, but the bones of it are the same. Since Varget and Berger 109 grain bullets are as easy to find as a leprechaun riding a unicorn, I figured building a training rifle would be a good idea. Up until this point, my primary training rifle was a .308 in an MDT ESS chassis, but I wanted to build a trainer in an ACC.

More: Building a 6mm GT for Competition

The action that I'm using is an Ultimatum Precision Deadline. This action is a Remington 700 semi-clone; we'll dive deeper into that towards the end of this article. The two main features of this action that caught my eye are the three-lug bolt, 60-degree throw, and a bolt face that can be switched between .223, .308, and magnum bolt face with relative ease.

Being able to switch bolt faces gave me the brilliant idea of having a 6mm barrel and a .223 barrel. I have been seeing more and more people shoot .223 Remington at matches, so I figured while this might be a trainer rifle, I can still shoot some matches with it. Because, why not? But here's the catch: I will be chambering the tube in .223 Ackley Improved.

If you're not familiar with AI cartridges, it's a .223 Remington with the shoulder of the case pushed forward a little to 40 degrees. The steep shoulder allows more powder to fit in the brass allowing for higher velocities. Initially, I thought about building a 6mm Dasher, but that seemed a little silly due to the lack of brass offerings and the tuning issues that go along with it. It also uses the same powder, bullet, and primer as the 6 GT.

The next thought was spinning up another 6 GT, but I would have to source more brass. 6 BR? Already have one in an ESS. 6x47 Lapua? Already have one of those, too, in a Remington 700. Could I just put that in the ACC? Sure. But I want to go back and forth with the .223 AI. That leaves me with the 6mm Creedmoor. Oddly enough, factory ammo is pretty easy to come by, and so is brass. I also have plenty of 105 and 108 grain 6mm bullets on the shelf and plenty of H4350. The hardest part would be sourcing dies.

The first barrel I turned was the 6mm Creedmoor. A Bartlein 1:8" twist Heavy Varmint tube finished at 25" and chambered with a Dave Mansion Precision SAAMI spec reamer. The .223 AI would have to wait due to a couple of bumps in the road, which we will talk about later in the article.

While waiting for my ACC, I decided to slap the barreled action into an ESS that I had floating around as a placeholder. This would allow me to at least break the barrel in and get a load developed. Along with the barreled action and ESS, the rifle consists of a limited Gold Edition Trigger Tech Diamond, Area 419 Hellfire Match, and American Defense Manufacturing Delta Mount carrying a Maven RS.4. If you haven't heard of Maven, they're a premium direct-to-consumer optic company specializing in hunting gear; the RS.4 is their "tactical" style optic, a 5-30x56. Great glass at a price ($1,800) makes the package a great value.

THE RESULTS

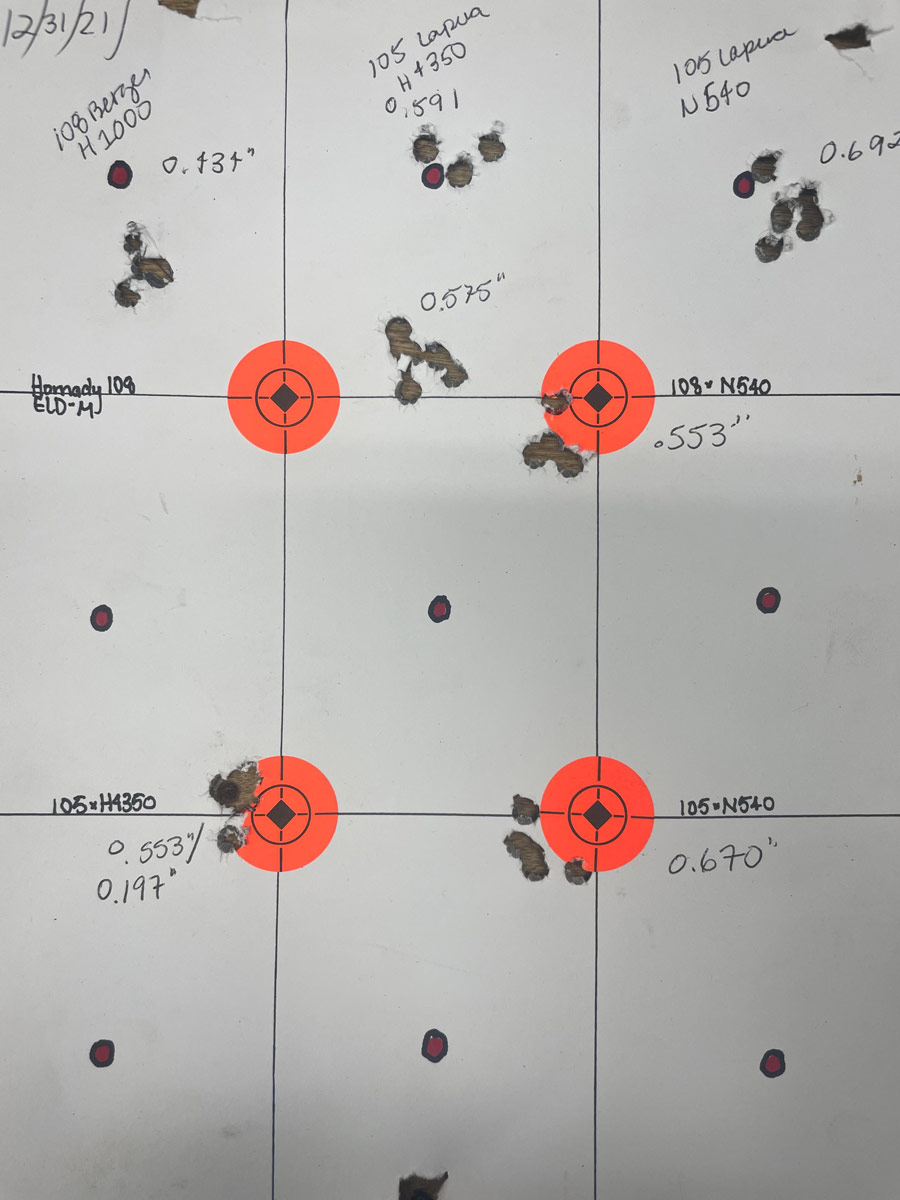

When I go to the range to break in a rifle that's chambered in something that I've never loaded before, I typically like to fireform 50 or 100 cases. I also like to test out different powder and bullet combos with a modest charge. I'll shoot 5 or 10 round groups, and typically one bullet-powder combo will separate itself from the rest, and I'll work up a load. In this case, it was H4350 and the 105-grain Scenar-L by Lapua.

More: 6mm GT Load Development

This rifle is an absolute hammer. The groups average in the ½ MOA area with velocities around 3050 FPS depending on conditions. The standard deviations sit around 4-6 FPS so I will call that a win.

Deadline Action and Deadline Compatibility Kit

Remember when I said there were a few curve balls? My ACC chassis arrived, so I dropped the barreled action in. Since the Deadline is based on a Remington 700 action, I assumed that it should be a drop-in and off to the races. I was mistaken. If I had done any reading on the subject, I would have found that the Deadline has a magazine stop that doesn't allow a typical AICS pattern magazine to seat properly. I tried to modify the magazines to work, but that was a borderline magazine-ruining mistake. I was delighted that MDT had a solution with their Deadline Compatibility Kit. I ordered one to remedy the issue and started testing immediately.

In Part 2, I am going to talk about the Deadline Compatibility Kit, .223 AI barrel and load development. Until then, I hope you enjoyed this article, and we'll see you in part 2!

ABOUT THE AUTHOR

William Maxwell currently serves in the United States Army. After returning from his first deployment in 2015, he started building firearms and focused heavily on pistol and carbine training. In 2018 he fell into the rabbit hole of precision rifle shooting. He spends his free time competing, reloading, editing digital content, and writing. He can be reached via Instagram @maddmaxxguns.

CAD

CAD

Euro

Euro